ELYRIA, Ohio — Driver-tested and fleet-proven, Bendix’s leading-edge commercial vehicle safety technologies are for the first time available through a retrofit upgrade program.

At present, Bendix offers retrofits of six safety technologies. In some cases, retrofitting requires the vehicle to come factory equipped with Bendix® ESP® full-stability technology:

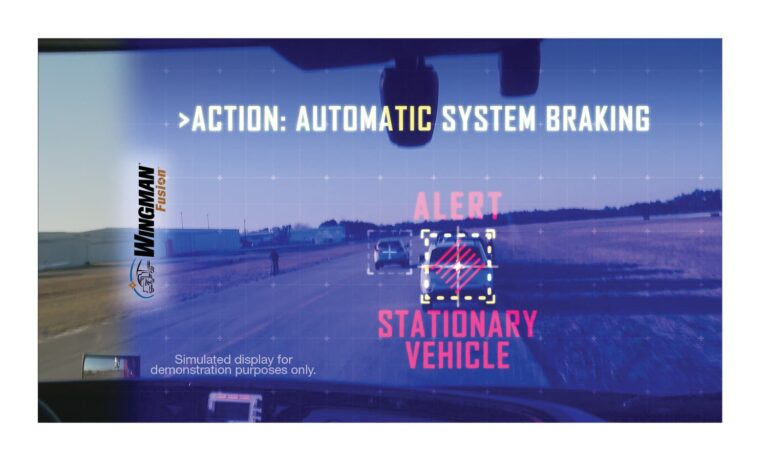

- Bendix Wingman Fusion

- Bendix Wingman Advanced – A Collision Mitigation Technology

- AutoVue 4G Lane Departure Warning (LDW) System by Bendix CVS

- Bendix BlindSpotter Side Object Detection System

- Bendix VORAD (Vehicle On-Board Radar) VS-500

- SafetyDirect by Bendix CVS

A slate of additional technologies, including the Bendix Intellipark Electronic Parking Brake, will continue to expand the scope of the program throughout 2019.

A unique, first-of-its-kind program that enables professional installation of Bendix advanced safety technologies to upgrade vehicles that did not come factory-equipped, the Bendix Retrofit Upgrade Program features two key elements: a comprehensive website that enables vehicle operators to determine retrofit opportunities per vehicle, and an escalating network of Bendix Authorized Retrofit Dealers and Distributors (ARDs) to facilitate the professional installation.

“Keeping a fleet equipped with the latest safety technology can be a never-ending challenge,” said TJ Thomas, Bendix director of marketing and customer solutions – controls. “It’s just not practical to scrap all your trucks and replace them overnight. The Bendix Retrofit Upgrade Program makes it possible to bring vehicles not originally built with selected safety systems up to speed with the latest increasingly essential systems. It helps enhance a fleet’s safety, while also contributing to an improved driver experience vehicle to vehicle.”

With a phased-in introduction that began in 2017, the program has already been eagerly adopted by a growing list of major fleets across North America, with upgrade installations taking place daily.

Offering 24/7/365 access with information and more, Bendix will launch a website in mid-May to serve as the hub of the Retrofit Upgrade Program: www.bendixcvsupgrade.com. The site allows fleets and vehicle operators to identify which retrofit upgrade options are available for specific vehicle make, model, and year configurations. It allows Bendix to connect registered customers with a network of Authorized Retrofit Dealers and Distributors that can assist fleets in securing Bendix retrofit installation and support.

According to Thomas, “The website is the essential first step in the equation. When it comes to the complexity of safety system retrofit upgrades, there’s no margin for maybe. That’s why the ability to retrofit any Bendix safety system depends on each vehicle’s specifications; given the build variability for each OE, and the vast array of aftermarket products that can be added, additional vehicle information is required to confirm retrofit compatibility on a specific vehicle.”

“Retrofitting safety systems is very technical work and care must be taken – with the help of a knowledgeable supplier – to do it properly,” Thomas said. “It’s critical that the configuration of the vehicle and the equipment already on it will integrate with the new capabilities to be added. That could mean some vehicles may be retrofit-capable, and some vehicles may not. In all cases, specialized retrofit expertise for evaluation and installation is crucial.”

Bendix has established a demanding training program specifically designed to certify technicians who already meet the company’s rigorous criteria. The training involves classroom and hands-on learning – as well as mandatory ongoing continuing education instruction – to prepare technicians for the unique technical challenges associated with these systems. Only these Bendix Certified Installers – trained and assessed by Bendix – have access to all the tools and information necessary for retrofitting Bendix technologies, and only Bendix Authorized Retrofit Dealers and Distributors have access to the Certified Installers.

With retrofits expected to be handled in hours – not days or weeks – the proper certification of installers is key to getting trucks on the road quickly with minimal disruption to fleet operations.

Like the Certified Installers, the ever-growing network of specially authorized outlets – the ARDs – have been vetted and trained to help vehicle operators understand system availability, what vehicles are compatible, scheduling, and more.

“This program is a massive step forward in terms of driver, vehicle, and highway safety, and we are already partnering with a number of major fleets across a range of vocations on retrofitting these technologies,” Thomas said. “That work helped pave the way for the full launch of the program. Additionally, with full stability a requirement on new Class 7 and 8 trucks, more vehicles will have the foundational components in place to add these advanced safety systems in the future – and that carries the potential for greater highway safety for everyone.”

The Bendix Retrofit Upgrade Program also provides the building blocks for more complex, integrated safety products yet to come.

“There’s a lot of enthusiasm and excitement about this program from fleets and vehicle owners alike,” said Thomas. “It offers a whole new opportunity for our customers to bolster their operations, support their driver retention programs, and enhance their bottom line. We’re proud of this effort as one more way that we’re working hand-in-hand with teams across the industry to shape tomorrow’s transportation together.”

Thomas said Bendix safety technologies – including all those within the Bendix Retrofit Upgrade Program – complement safe driving practices and are not intended to enable or encourage aggressive driving. No commercial vehicle safety technology replaces a skilled, alert driver exercising safe driving techniques and proactive, comprehensive driver training. Responsibility for the safe operation of the vehicle remains with the driver at all times.

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.