AVON, Ohio — The end of the calendar year will mark the completion of the Environmental Protection Agency’s (EPA) Copper-Free Brake Initiative, and Bendix Commercial Vehicle Systems (Bendix) is reminding industry professionals to make sure they are compliant with the required changes in the OE and aftermarket air disc brake (ADB) and drum brake friction formulations.

“Now that the final phase of the Copper-Free Brake Initiative is almost complete, it’s important for fleets, distributors, and owner-operators to know what they are getting on their vehicles and understand what replacement pad options will be available to them,” said Keith McComsey, Bendix director of Air Disc Brake & Systems product group. “Selecting the right replacement pads – with an eye on the final and most stringent formula regulations – and supporting them with proper maintenance practices will help customers get the best performance and service life from their ADB system.”

According to a company press release, Bendix, will make new friction offerings available as the previously compliant materials are phased out.

A Decade Toward Copper-Free Brakes

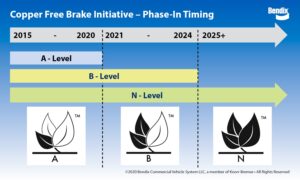

In January 2015, organizations within the automotive and commercial vehicle industries – including trucking – signed on to the Copper-Free Brake Initiative, along with the EPA and the Environmental Council of the States. The action was taken because copper from stormwater runoff can be harmful to the environment, affecting plants and animals – and when used in brake pads, it makes its way into the air and water through the fine dust released from friction during braking. (Copper was not the only material covered: The agreement also reduces the use of other substances in brake pads, including mercury, lead, asbestos, chromium-6 salts, and cadmium.) The initiative outlined a three-phase process regulating brake friction composition: A-Level compliance began in 2015, B-Level compliance was required beginning in 2021, and N-Level compliance begins Jan. 1, 2025.

According to the release, sustainability is a core value for Bendix and its parent company, Knorr-Bremse, and Bendix is committed to developing technology solutions that promote cleaner air, reduce fuel usage and ensure progress toward a new generation of cleaner vehicles.

“We’re providing our customers with N-Level friction offerings as required by the EPA’s Copper-Free Brake Initiative, and we’re pleased to help customers meet their own sustainability goals as well,” McComsey said.

Bendix Air Disc Brakes and Final Phase Compliance

N-Level compliance limits the amount of copper to no more than 0.5% by weight. The agreement also commits participants to taking steps to educate the automotive and trucking industries on the changes and provides guidelines for marking and labeling friction material packaging and products.

“All Bendix B-Level frictions will be phasing out of production at the end of 2024,” McComsey said. “We’re making our customers aware of the impending change and referring them to the compliant friction.”

The B-Level frictions that will be phased out include both the Bendix BX276 OE-level friction and the aftermarket BA236. The suitable N-Level copper-compliant replacement is the Bendix BX277 pad, which is an OE-level pad ramping up in production in late 2024 for the North American market. Bendix will also launch the BA237 pad in early 2025, an aftermarket friction that is N-Level copper compliant.

Bendix parts and replacement kit numbers involved are:

- BX276 (K129276) – phasing out of production in Q4 2024.

- BA236 (K182236) – phasing out of production in Q4 2024.

- BX277 (K297277) – ramping up production in Q4 2024; N-Level compliant.

- BA237 (K182237) – coming in early 2025; N-Level compliant.

According to the release, customers can continue to use B-Level friction until 2035 as long as it was manufactured before Jan. 1, 2025. There will be no Bendix B-Level friction produced beyond 2024, so all Bendix friction will therefore be compliant until 2035. Customers in California and Washington are subject to certain restrictions and should consult California Health and Safety Code HSC 25250.52 – 25250.53 and Washington RCW 70A.340.030. For more information, see the Bendix Part Number Update PNU-300 in the document library on B2Bendix.com or call the Bendix Tech Team at 1-800-AIR-BRAKE (1-800-247-2725).

The release also noted that drum brake friction must also meet the N-Level requirements. Most Bendix drum brake friction was already N-Level copper compliant. The one offering that is not compliant (ES600) will be obsoleted at the end of 2024.

Safer, Cleaner Trucks and Roads

“We’ll be ready to help our customers meet the new regulations that take effect on Jan. 1, 2025,” McComsey said. “Moving forward, we’ll continue to focus on optimizing friction for specific applications and improving the friction-couple performance between the rotor and pad so our customers can enjoy longer service life and lower total cost of ownership.”

Worldwide, Bendix and its parent company, the Munich, Germany-based Knorr-Bremse, maintain global leadership in ADB production at over 60 million brakes and counting.

“Bendix wheel-end solutions include air disc and drum brake systems, automatic slack adjusters, spring brakes, and friction that provide lower total cost of ownership while delivering on safety, stopping power and reliability,” the company said in the release. “The company’s ever-growing portfolio of air management, braking, and safety technologies deliver on areas critical to the success of fleets and owner-operators: safety, equipment reliability, performance and efficiency, and lower total cost of ownership. By encouraging investments toward enhancing driver and vehicle safety, Bendix supports the commercial vehicle industry’s pursuit of safer roads for all who share them.”