Make sure the used truck you buy is the right one for your business

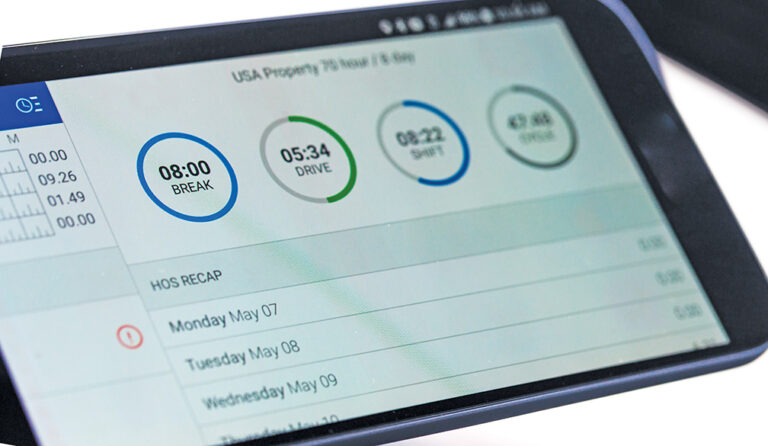

Purchasing a used tractor for your business is a difficult task any time. Purchasing one today is even tougher. High prices and low inventories have made the task of finding and financing a used truck much more difficult than in years past. At the same time, record high freight rates have made owning and operating your own truck an attractive proposition. As carriers complain about the shortage of qualified drivers available to hire, owner-operators benefit in two ways — some carriers are improving compensation packages for owners who lease on their equipment, while those who remain independent find more freight to haul. Those who are determined to buy a tractor right now should follow a simple process to make sure the truck is suited to the intended job. Unfortunately, the first thing most buyers do is look at a truck. Nice paint, shiny chrome and a like-new interior can help create a sense of desire, or at least comfort, before the buyer considers more important items. Before looking at a truck, get some information. Start with the mileage, but also ask about the vehicle’s accident history and maintenance records. Check for major repairs, even if they were done under warranty, and look to see if maintenance schedules were closely followed. Tires and brakes aren’t cheap, so you’ll want to get as many miles as possible before replacement. Those tires may be new — but used trucks often come with recapped tires. Recaps are fine in most cases, especially if the entire set was recapped together. However, you should be wary of recaps on mixed tire brand casings or different tread patterns. Find out when the last brake job was done and if rotors or drums were replaced or turned. When it comes to the engine, consider more than horsepower. For years, the 15-liter engine was the industry standard, but modern 13-liter engines can produce adequate horsepower with less weight and using less fuel. Some 13-liter power plants also require special oils and filters and can cost more to maintain; they may also detract from the truck’s resale value. Consider your routes, too. If you expect to be pulling heavy loads through mountainous regions, the 15-liter engine might be a better choice. Automated transmissions are becoming more popular than ever. They may cost a little more, but the savings in fuel cost that result from computer-controlled shifting should return the investment quickly. Keep in mind, however, that at resale time, it may be more difficult to find a buyer. If you prefer a manual transmission, the number of gears needed might depend on the intended use. Nine or 10 speeds is plenty for regular hauls; 13- or 18-speed transmissions provide more options for hauling heavy loads or traveling less-than-ideal roads. The third key point in the drive train is the differential, or “rear-end.” A key word in modern truck specifications is “downspeeding.” Trucks that are primarily used for long-haul interstate routes are often built with a lower axle ratio designed to keep engine RPMs lower at highway speeds. The axle ratio measures the number of splines, or “teeth,” on the ring gear of the differential divided by the number of splines on the pinion gear attached to the driveshaft. An easier explanation is that the ratio denotes the number of driveshaft spins it takes to turn the drive wheels one turn. The problem is, as axle ratios decrease so does the available torque available for power when needed. Simply put, a lower axle ratio provides better fuel mileage at the expense of power. That’s good if nearly all the expected driving will be on interstate highways pulling common loads. It’s not so good pulling extra-heavy loads or in stop-and-go traffic situations. In those cases, U-joints and other drivetrain components may wear faster. Another drivetrain consideration is whether the axle configuration is 6X4 (much more common) or 6X2. The six denotes how many wheel positions are on the vehicle; the second number indicates how many of them are powered by the drivetrain. In a 6X2 setup, only one axle “pushes” the vehicle. That’s good for fuel mileage but bad for traction in slippery conditions. Advanced driver-assistance systems (ADAS) are becoming more popular. Used trucks may be equipped with features such as lane-departure warnings or even steering assist, adaptive cruise control, side object detection and automatic braking. These systems increase driver safety, but they can also increase both purchase and maintenance costs. Most have sensors that can require replacement. A critical factor to ask about is whether the vehicle is covered by warranty. Some new truck warranties are transferable to the next buyer, and some truck dealers offer warranties on used models. In many cases, dealers work with a third-party warranty service, or you may choose to work directly with a service provider. Warranty coverage can offer some comfort, but make sure you understand the cost and any conditions that apply. For example, a purchased warranty may require that your truck be repaired only at certain facilities. Finally, it’s always a good idea to have your own mechanic check out a used truck. A trusted technician will know how to determine wear, and can often determine which parts have been replaced. A thorough inspection can disclose unreported problems or even accident damage you may not have seen. At a minimum, a third party should conduct a thorough DOT inspection on the vehicle. Most dealers will work with you to make sure you’re satisfied with the condition of the truck you’ll be depending on for a long time. After all of that, it’s time to admire that paint and chrome, and to climb up in the cab to check it out. You’ll be confident you’ve chosen the right piece of equipment and that it’s in the best operating condition it can be, allowing you to concentrate your efforts on running your business.