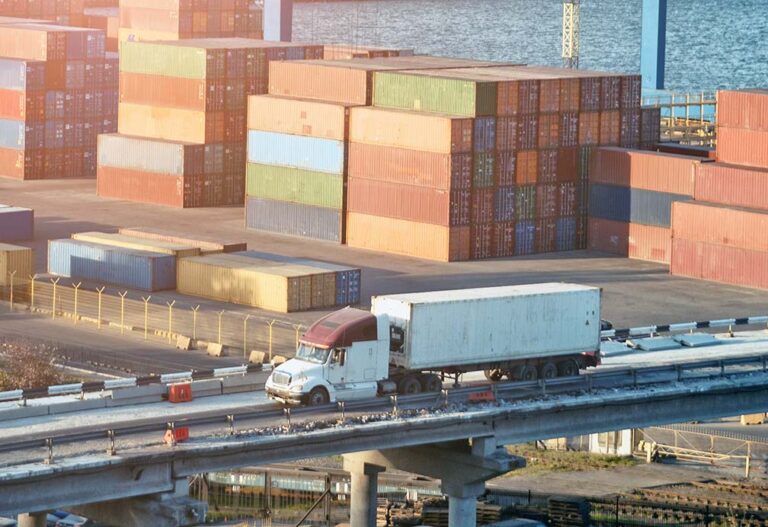

CH Robinson utilizing artificial intelligence to process shipping quotes

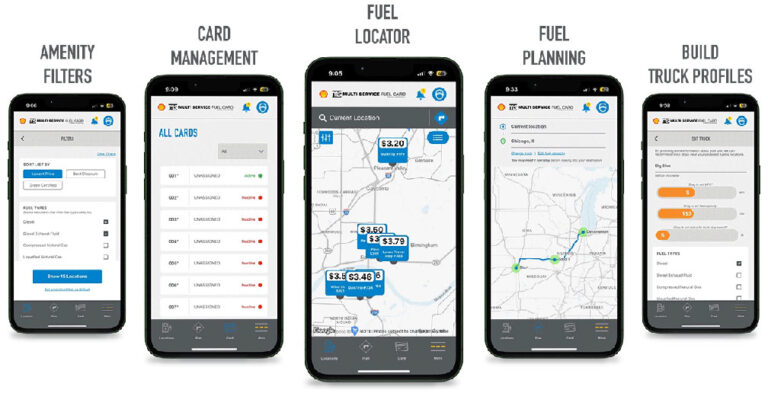

EDEN PRAIRIE, Minn. — These days, artificial intelligence (AI) is popping up in every imaginable industry. Trucking is no exception. Though some in the industry have pushed back against the budding technology, others are embracing it. Third-party logistics giant C.H. Robinson is one of them. The company has announced it’s now operating an AI protocol to help shippers across the country. “It breaks a long-standing barrier to automation and gives shippers who use email the same speed-to market and cost savings as shippers who are more digitally connected,” a C.H. Robinson news release notes. Using artificial intelligence, C.H. Robinson’s new technology classifies incoming email, reads it and replicates the steps a person would take to fulfill a customer’s request. For example, shippers often still choose to send an email asking for a price quote rather than log into a digital platform. On an average business day, the global logistics company receives over 11,000 emails from customers and carriers requesting pricing on truckload freight. “Our customers can get instant price quotes through our Navisphere platform or any of the 35 largest TMS or ERP systems we’re integrated with. But for someone like a busy warehouse manager with unexpected spot freight or freight in a new lane, an email can just feel easier. Email works the same for everybody. It doesn’t ask for your password. There are no fields to fill in,” said Mark Albrecht, vice president for artificial intelligence. “Before generative AI, replying to that email request defied automation. Customers had to wait for a human just to pass along a quote from our Dynamic Pricing Engine. Now, our new technology reads the email and supplies the quote in an average 2 minutes 13 seconds. C.H. Robinson is doing this at scale, leaving our people more time to help those same customers with more complex requests.” While the technology is replying to 2,000 customer quote requests a day, it opens the door to automating other transactions shippers and carriers choose to do by email. The large language model (LLM) the technology uses can be trained to identify an email about a load tender, a pickup appointment or a shipment tracking update. For spot quotes, C.H. Robinson has already trained the model to differentiate between a quote request for truckload, less-than-truckload (LTL), intermodal or air freight. So far, 2,268 of C.H. Robinson’s truckload customers are getting the benefits of automated email quotes. The faster a shipper gets a price quote and secures a carrier to pick up their freight, the less likely they’ll need to pay a premium. Speed matters in the spot market because most carriers are regional and only so many are working a given shipping lane on a given day. MIT research shows that shippers delayed in getting to the spot market can end up paying 23% to 35% extra on their shipment. C.H. Robinson developers are now working on applying the technology to LTL price requests, which will be especially valuable to the company’s portfolio of small-business customers that rely on email. A pilot using AI for price requests on expedited freight is also under way, with automotive customers that ship parts critical to just-in-time manufacturing. “After automating so many other types of customer transactions, you could call email the last mile,” said Arun Rajan, C.H. Robinson’s chief operating officer. “We’d been exploring how to automate email requests for a couple of years through natural language processing and machine learning, but it would’ve been insanely hard and expensive. Then generative AI arrived, and we developed this automation technology so fast because we already had training data ready to go. The good news for our customers is that they still get what they need using email, while our supply chain experts are freed up to do work that’s higher value for them, our customers and our company’s growth.”