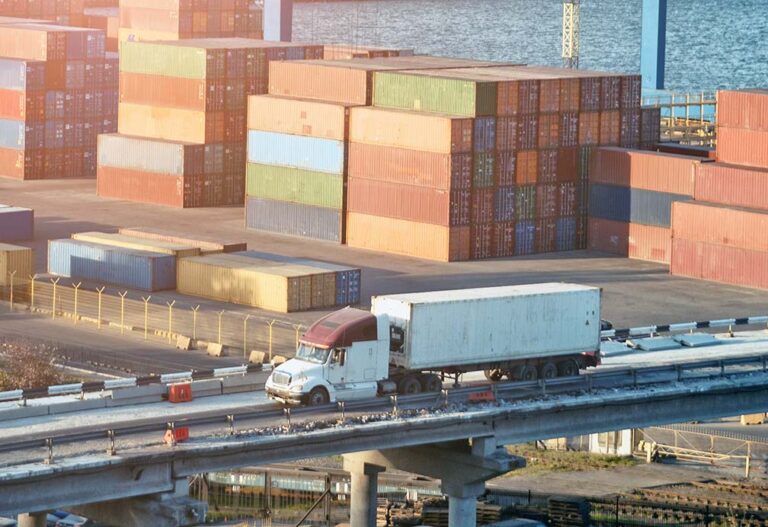

PITTSBURGH — On a three-lane test track along the Monongahela River, an 18-wheel tractor-trailer rounded a curve. No one was on board. A quarter-mile ahead, the truck’s sensors spotted a trash can blocking one lane and a tire in another. In less than a second, it signaled, moved into the unobstructed lane and rumbled past the obstacles. The self-driving semi, outfitted with 25 laser, radar and camera sensors, is owned by Pittsburgh-based Aurora Innovation. Late this year, Aurora plans to start hauling freight on Interstate 45 between the Dallas and Houston areas with 20 driverless trucks. Within three or four years, Aurora and its competitors expect to put thousands such self-driving trucks on America’s public freeways. The goal is for the trucks, which can run nearly around the clock without any breaks, to speed the flow of goods, accelerating delivery times and perhaps lowering costs. They’ll travel short distances on secondary roads, too. The companies say the autonomous trucks will save on fuel, too, because they don’t have to stop and will drive at more consistent speeds. The image of a fully loaded, 80,000-pound driverless truck weaving around cars on a super-highway at 65 mph or more may strike a note of terror. A poll conducted in January by AAA found that a decisive majority of Americans — 66% — said they would fear riding in an autonomous vehicle. But in less than nine months, a seven-year science experiment by Aurora will end, and driverless trucks will start carrying loads between terminals for FedEx, Uber Freight, Werner and other partners. Aurora and most of its rivals plan to start running freight routes in Texas, where snow and ice are generally rare. For years, it seemed as though the initial venture for autonomous vehicles would be ride hailing in large cities. But General Motors’ Cruise robotaxi unit is struggling in the aftermath of a serious crash. And Alphabet’s Waymo faces opposition to expanding its autonomous ride service in California. The result is that self-driving trucks are poised to become the first computer-controlled vehicles deployed in widespread numbers on public roads. The vehicles have drawn skepticism from safety advocates, who warn that with almost no federal regulation, it will be mainly up to the companies themselves to determine when the semis are safe enough to operate without humans on board. The critics complain that federal agencies, including the National Highway Traffic Safety Administration, take a generally passive approach to safety, typically acting only after crashes occur. And most states provide scant regulation. But Aurora and other companies that are developing the systems argue that years of testing show that their trucks will actually be safer than human-driven ones. They note that the vehicles’ laser and radar sensors can “see” farther than human eyes can. The trucks never tire, as human drivers do. They never become distracted or impaired by alcohol or drugs. “We want to be out there with thousands or tens of thousands of trucks on the road,” said Chris Urmson, Aurora’s CEO and formerly head of Google’s autonomous vehicle operations. “And to do that, we have to be safe. It’s the only way that the public will accept it. Frankly, it’s the only way our customers will accept it.” Phil Koopman, a professor at Carnegie Mellon University who studies vehicle automation safety, said he agreed that self-driving trucks can theoretically be safer than human-driven ones — for the very reason that they lack drivers who might become distracted or impaired. But he cautioned that the vehicles’ computers inevitably will make errors. And just how the trucks will fare in real-world situations, he said, will depend on the quality of their safety engineering. With billions of dollars in investments at stake, Koopman said, he wonders how the companies will balance safety decisions against cost concerns. “Everything I see indicates they’re trying to do the right thing,” he said. “But the devil is in the details.” On the test track, reporters saw Aurora’s semis avoid simulations of road obstacles, including pedestrians, a blown tire, even a horse. But the trucks were running at only 35 mph (56 kilometers per hour) in a controlled environment with nothing unexpected happening. (The trucks are being tested with human safety drivers on Texas freeways at speeds of 65 mph (105 kph) or higher.) On the track, the trucks spotted obstacles more than a quarter-mile away and acted immediately to avoid them. Urmson said the trucks’ laser sensors can detect people walking on a highway at night, far beyond the distance of headlights. Since 2021, Aurora trucks have autonomously hauled freight over 1 million miles on public highways — but with human safety drivers in the cabs. There have been only three crashes, Urmson said, all of them caused by mistakes by human drivers in other vehicles. A federal database that started in June 2021 shows at least 13 crashes with other vehicles involving autonomous semis, including three involving Aurora. In all the cases, the crashes were caused by other vehicles changing lanes or rear-ending the trucks. Sometimes, human safety drivers took over just before the crash. Aurora won’t compromise safety, Urmson said, even if ensuring it might delay the timetable for achieving a profit. “If we put a vehicle on the road that isn’t sufficiently safe — that we aren’t confident in the safety of — then it kills everything else,” he said. Last month, when Urmson displayed the trucks to Wall Street analysts in Pittsburgh, he said the publicly held company expects to turn a profit by late 2027 or early 2028. To meet that goal, Aurora must succeed in putting thousands of the trucks on the roads, hauling freight from terminal to terminal and collecting a per-mile charge from customers. The company’s competitors — Plus.ai, Gatik, Kodiak Robotics and others — also plan soon to put driverless trucks on the roads hauling freight for customers. Gatik expects it to happen this year or next; the others haven’t set timetables. Don Burnette, CEO of Kodiak, said freeways are a better environment for autonomous vehicles than congested cities where ride-hailing robotaxis have been running. There are fewer pedestrians, and fewer unexpected things happen. Still, there are higher speeds and longer braking distances. In testing on highways with human backup drivers, Burnette said, Kodiak has never experienced a crash in which its trucks were at fault. “At the end of the day,” Burnette said, “these trucks should be much safer than human drivers.” Almost every year in the United States, a tractor-trailer plows into traffic that is stopped because of road construction, often causing deaths and injuries. By contrast, Burnette said, autonomous trucks pay attention all the time and are always watching 360 degrees. Perhaps so. But at a Buc-ee’s mega convenience store and gas station along Interstate 45 about 35 miles south of Dallas, the prospect of driverless semis struck a note of fear. “It sounds like a disaster waiting to happen,” said Kent Franz, a high school basketball coach in Chandler, Oklahoma, who was traveling to Houston for a wedding. “I’ve heard of the driverless cars — Tesla, what have you — and the accidents they’ve been having. Eighteen-wheelers? Something that heavy, relying on technology that has proven it can be faulty? Doesn’t sound very comfortable to me.” Patti Pierce, a retired accountant from Plano, Texas, said she would be OK with the technology — in about a decade. “I don’t want to be on the road with them right now,” she said. “I like the gadgets in my car, but I’m not sure the technology is good enough right now to have a truck that drives itself.” No federal regulations specifically cover autonomous vehicles, Koopman of Carnegie Mellon noted. Most states have no such regulations, either. Koopman said the automated-vehicle industry has persuaded many states to bar local governments from enacting such regulations. The result, he said, is that the public must trust the companies that are deploying autonomous semis. The National Highway Traffic Safety Administration and the Federal Motor Carrier Safety Administration, both part of the federal Department of Transportation, lack authority to stop autonomous vehicles from going on the roads. If something goes wrong, though, they can require recalls or order trucks out of service. “You can’t expect the government to protect you here,” Koopman said. “The company’s going to decide when they think they’re safe, and the only thing the regulator is going to do is judge them after the fact.” For the past five years, the motor carrier administration has been preparing safety standards for trucks with automated driving systems. The standards will govern inspections, maintenance and the remote monitoring of the trucks. But it’s unclear when the rules will emerge from the regulatory process. In the meantime, the autonomous semi companies say they can help address a truck driver shortage, estimated by the industry to amount to 64,000 drivers. Yet there also are worries that autonomous trucks eventually will supplant human drivers and cost them their livelihoods. The Teamsters union, which represents about 600,000 drivers, most of them truckers, is pushing state legislatures to require human drivers to monitor the self-driving systems, contending that they are unsafe. A 2021 Transportation Department study concluded that the nationwide use of fully automated semis was years away, giving drivers time to transition to other transportation and logistics jobs that will be created. Aurora’s Urmson said he thinks driverless semis will complement the work already done by human drivers, because many more goods will have to be moved for a growing population. “If you’re driving a truck today,” he said, “my expectation is you’re going to be able to retire driving a truck.”