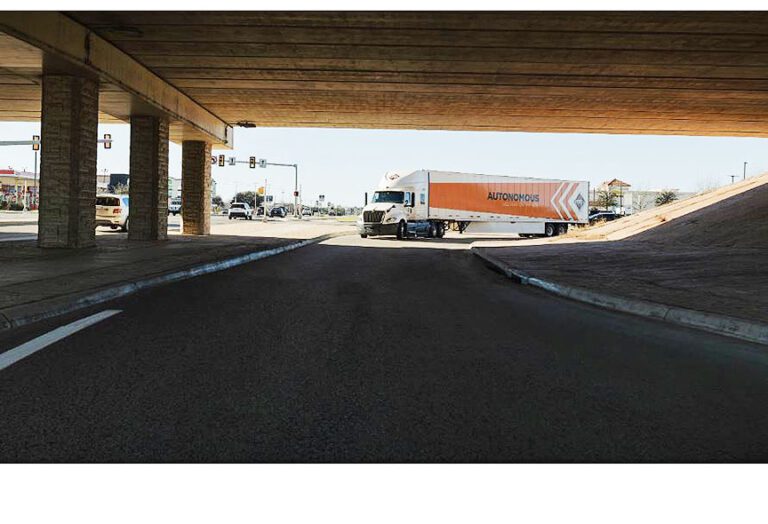

There is little doubt that the implementation of autonomous trucks will increase the efficiency of freight operations once the technology is widely available and legal to operate in enough areas. According to proponents, autonomous vehicles address too many issues in the trucking industry to be ignored. “I think that the supply chain crisis and the progress on the technology have convinced a lot of the key voices in the trucking industry that this technology is here and more to the point, this technology is really necessary,” said Dan Goff, director of external affairs at Kodiak Robotics. “There’s really nothing else coming down the pike that can solve some of the issues that the trucking industry faces, particularly around driver recruiting and retention.” Ann Rundle, vice president of electrification and autonomy for ACT Research, points to the overall industry efficiency that can be afforded by automation. “You would never have a factory designed to run one shift, right? A Class A tractor is just that,” she explained. “It is a factory, and it’s running one shift. But what if you could have that factory, i.e., that truck, running three shifts?” Carriers and truck makers have partnered with autonomous truck developers to bring the technology to real-world applications, hauling freight in several Southern states under the watchful eye of drivers who, while capable of taking control as needed, also provide valuable feedback about vehicle performance to developers. The past year, however, has seen the falling away of some key players in the race to integrate autonomy in the trucking industry. Pittsburgh-based Locomation laid off its workforce and shuttered operations. San Francisco-based Embark Trucks was acquired by Applied Intuition. Google’s WAYMO ceased its autonomous truck program in July. Also last year, TuSimple announced it was ceasing its U.S. based operations to focus on its China structure. The company is currently under investigation by the FBI and the U.S. Securities and Exchange Commission for its failure to disclose ties with Hydron, a Chinese tech company. However, there are other autonomous truck developers still going strong — Kodiak Robotics, Aurora and its partnership with Continental and Torc Robotics, along with Volvo Autonomous Solutions. “I think 2024 is really gonna be the key year,” Goff said. “I think this year is the first year where we’re going to see some kind of real driverless trucking happening on the road. It’s going to be limited, but I think this is the year that we really show that this is going to happen.” As the technology gets closer to widespread use, legislators are weighing in on the operation of autonomous vehicles, particularly commercial trucks, within the boundaries of their jurisdictions. “People are worried about a heavy truck without a driver, run by a computer,” Rundle said. “They’re more worried about that than about the driver who is distracted or drowsy or whatever. They’re more worried about no driver than a driver that shouldn’t be driving.” In Indiana, Senate Bill 57 would require that a human operator licensed to operate an autonomous vehicle be physically present and able to take control, if necessary. In New York, Senate Bill 7758 would require a “natural person holding a valid license” be present inside an automated commercial vehicle. The California legislature passed Assembly Bill 316, requiring human operators in commercial vehicles, only to see it vetoed at the desk of Gov. Gavin Newsom. While safety is often cited as a reason for demanding the presence of qualified drivers in autonomous trucks, other motives are often in play. The International Brotherhood of Teamsters, for example, has a vested interest in legal mandates for employees they can organize. Some legislators have talked of preserving jobs and saving communities. But, just as safety is currently an argument used against driverless trucks, safety will also be an argument used to make them mainstream. “(The autonomous system is) looking 360, and it’s looking forward,” Rundle explained. “It’s actually able to see better than any good truck driver would and then also, there is no such thing as a blind spot anymore, right?” Even the best of drivers can’t concentrate on the view ahead, behind and along both sides plus gauges all at the same time, she noted. “But a computer CAN do that, because the computer is five different sets of eyes,” she said. The drawback to autonomous technology, according to Goff, has been redundancy. “You basically have a set of computers talking to a set of actuators,” he explained. “Those actuators are pretty reliable — but nothing in life is 100% reliable, and it’s a lot of risk to put responsibility for an 80,000-pound truck on say, a single steering actuator.” Without a driver present to override the system, redundancy provides autonomous equipment with a failsafe that prevents accidents. “Last week, we actually were the first company to unveil a fully redundant driverless ready hardware,” Goff told Truckload Authority in late January. “That’s going to be the platform that we use for our first driverless runs later this year, and that’s really one of the prerequisites to driverless operations at scale.” At ACT Research, Rundle’s team monitors the progress of autonomous trucking technology and has forecasted its acceptance in the trucking industry. “In our forecast, we looked primarily at Class A tractors, we looked a little bit medium duty,” she said. “We see it coming as a very measured deployment, starting in Texas and then moving out where regulations allow.” The ACT team predicts that 10% to 14% of the tractor population will be driverless by the year 2040. Forecasts will change, of course, with further technology development and new regulations put in place, and forecasters will be revising predictions accordingly. Rundle pointed out that some segments of trucking that require driver attendance, such as flatbed and livestock, may never be automated. Goff remains committed to progress. “We need this technology. We do not have enough people to keep our supply chains moving,” he said. “Your readers are well aware that the driver shortage is real — it’s growing. It’s a massive economic threat.” While many newer tractors are equipped with autonomous features, such as lane-departure alerts, automatic emergency braking, and more, the widespread use of completely autonomous rigs remains on the horizon. Photo courtesy of Kodiak Robotics This article originally appeared in the March/April 2024 edition of Truckload Authority, the official publication of the Truckload Carriers Association.