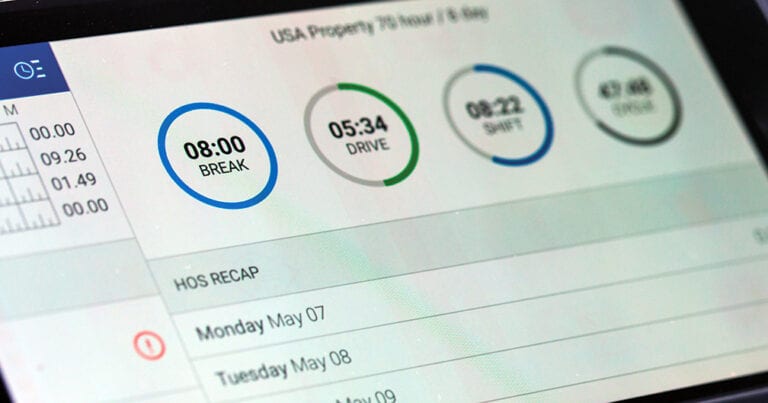

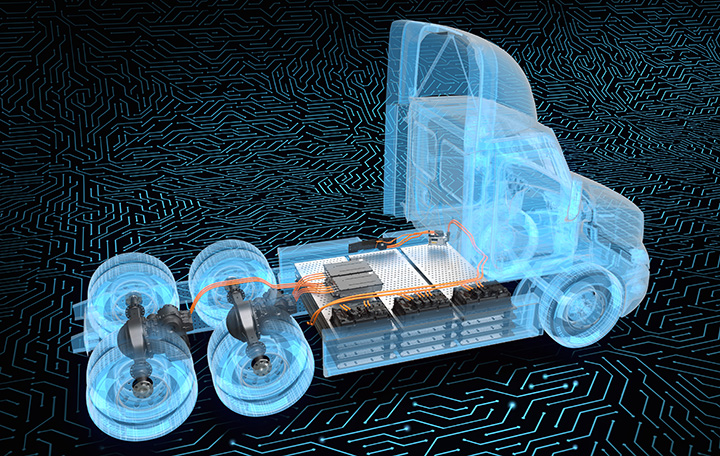

KIRKLAND, Wash. — Kenworth on Feb. 11 launched a new generation of its on-highway T680 flagship, building on the success of the classic T680. The Kenworth T680 Next Gen offers technology advancements, including an innovative 15-inch digital display, Next Gen SmartWheel, fully LED headlamps, under-the-vehicle airflow management, additional advanced driver-assistance systems (ADAS) and a sleek high-tech design that balances aerodynamics and serviceability. “The Kenworth T680 Next Generation raises the bar for overall excellence, superior fuel efficiency, outstanding performance and bold styling,” said Kevin Baney, Kenworth general manager and PACCAR vice president. Engineers at Kenworth worked to craft the T680 Next Gen with a highly effective aerodynamic package to reduce drag and increase fuel efficiency. “We exceeded the superior fuel efficiency of the current T680, through aerodynamic advancements and design innovations. As a result, the Kenworth T680 Next Generation is the most aerodynamic truck in company history,” said Joe Adams, Kenworth chief engineer. The T680 Next Gen includes a new aero bumper and hood, turning vanes, durable lower fairing extensions, chassis fairings, wheel well closeouts, 28-inch side extenders, tandem drive axle fairing, and wheel covers, among other features — all designed to keep the airflow closer to the cab and reduce drag-causing turbulence. The T680 Next Gen is standard with the EPA 2021 PACCAR MX-13 12.9-liter engine and PACCAR Powertrain that also offer strong fuel efficiency gains. “It’s striking,” said Jonathan Duncan, Kenworth’s design director. “When you look at the Kenworth T680 Next Generation, the first thing you notice are the headlights and the new hood and grille that set up the truck’s expression and feel. It really is a cool-looking vehicle.” The bottom line is up to an estimated 6% overall fuel economy increase for a T680 Next Gen 76-inch sleeper over a comparably spec’d T680 with an EPA 2017 PACCAR MX-13 engine, Adams said. The EPA 2021 PACCAR MX-13 engine features enhanced durability, reduced complexity, performance upgrades, increased downspeeding capability and more efficient combustion. The result is more power, longevity, uptime, ease of service and driver satisfaction, according to a company statement. The PACCAR MX-13 engine produces a smooth-operating, high-performance powertrain, optimized for a seamless integration with the PACCAR 12-speed transmission and PACCAR 40K axles. “The T680 Next Gen hit our design goal of being sleek and sophisticated. We wanted to focus on the aerodynamics, the technology and the refinement, and make the styling show that is a world class, high-performance machine,” Duncan said. The T680 Next Gen with a Diamond VIT interior has a rich madrona insert in the door pad with black stitching to match the black door. The Diamond VIT sleeper interior has fine black Diamond panels with madrona stitching — also offered on the leather-wrapped steering wheel. T680 Next Gen with 76-inch high-roof sleepers can be spec’d with the optional Kenworth Cargo Shelf, a 5.5-inch storage shelf with multiple secure tie-down points. Two LED lights on the shelf’s underside provide lower bunk lighting. The cab features a new 15-inch high-definition, fully digital display — the largest standard factory display available in any North American truck to date. The design is easily adjustable to enable drivers to match their preferences, while also automatically displaying critical content. The Kenworth T680 Next Generation is designed to optimize performance in line haul, pickup and delivery, and regional haul operations. Available in day cab, 40-inch, 52-inch and 76-inch-sleeper configurations, the T680 Next Gen is standard with the proprietary PACCAR Powertrain featuring the 2021 PACCAR MX-13 engine, PACCAR 12-speed automated transmission and PACCAR 40K tandem rear axles. “The Kenworth T680 Next Generation has great innovations, new technologies and outstanding fuel efficiency, but this truck is all about the drivers. We built this truck around them and for them. The T680 Next Gen provides drivers with the convenient, next generation SmartWheel, new customizable 15-inch Digital Display, excellent forward lighting down the road, additional advanced driver assistance systems, and, of course, a premium and extremely comfortable cab and sleeper,” said Laura Bloch, Kenworth assistant general manager for sales and marketing. “This is the next generation of The Driver’s Truck and offers the full Kenworth Experience.” Other features and extra touches on the Kenworth T680 Next Generation models include the following: Kenworth advanced driver-assistance systems (ADAS): The T680 Next Gen offers a suite of ADAS, introducing lane-keeping assist and torque-assisted steering as options for the first time in the Kenworth lineup. Lane-keeping assist uses camera input to identify when the truck is departing the lane and provides a “nudge” to help keep the vehicle centered in the lane. This feature requires Bendix Fusion and comes with torque-assisted steering, which provides additional torque to the steering column, reducing driver fatigue. The T680 Next Gen also includes adaptive cruise control, lane-departure warning, collision mitigation and side object detection. Bluetooth microphone: A new Bluetooth microphone is located near the CB tray in the header. Bumper and under-truck airflow management: The restyled aerodynamic bumper maintains the same approach angle and ground clearance as the classic Kenworth T680. The bumper has an improved profile to direct air past the wheel openings, improving aerodynamics. The unique air dam design guides and controls airflow under the chassis while providing protective coverage under the cooling module. It features an offset radar, allowing for a robust center-mounted license plate holder. Hood: A sleek new aerodynamic hood includes a bold air-intake system design, hood air vent for aero benefit, a narrower grille and stylish, high-visibility side turn indicators. The hood is available in two sizes — 125-inch BBC (standard) or 119-inch BBC (MX) — with fairings or a split fender setup. Kenworth TruckTech+ remote diagnostics: The system enhances vehicle diagnostics by providing engine health information for Class 8 Kenworths to fleet managers and Kenworth dealers. The system diagnoses any issues and provides recommended solutions to the driver and fleet manager. The system is standard on the T680 Next Gen. Lighting: Fully LED headlamps provide a crisp, bright light that produces visibility that’s critical in the trucking industry. A built-in infrared heater quickly clears ice and snow. The headlamps include low beam, high beam, a signature daytime running lamp and turn signals. Newly designed halogen headlamps flow with the hood and integrate daytime running lights and an amber turn signal. A new LED side turn indicator offers increased visibility to surrounding traffic. The indicator is standard with all hood options. Next Gen Kenworth SmartWheel: The new standard Kenworth SmartWheel — made of polyurethane or optional leather — features intuitive controls for the new standard 15-inch digital display. Featured switches are based upon vehicle specification. The new digital instrumentation system allows seamless viewing selection between two minimized views, basic view, maximized view, and even a driver-customizable favorites view. Drivers can easily scroll up and down this hierarchy using the standard Next Gen Kenworth SmartWheel, which also puts cruise control and radio functions at the driver’s fingertips. Seats: The seats offer new cover options of leather, ultrafabrics, fabric and vinyl combination, vinyl only, and fabric only. The signature Kenworth Diamond VIT and Vantage motifs are available in tan and gray. Diamond VIT interiors feature madrona-colored door inserts and wood grain accents. Sleeper: T680 Next Gen with 76-inch high-roof sleepers can be spec’d with an optional upper 5.5-inch in-depth storage tray. Two LED lights on the tray’s underside provide lower bunk lighting. Stairlike entry: While the team created even more new aerodynamic touches from the cab back, they also redesigned the steps into the cab with a more stair-like entry. Wheelbase reduction: Improved chassis packaging is offered, presenting the opportunity for a shorter wheelbase and a reduced trailer gap of between 38 to 42 inches. Sleeper side extenders are designed to open to allow for frame access with the tighter trailer gap. A lighter front axle and lower ply tires can be spec’d for cost savings.