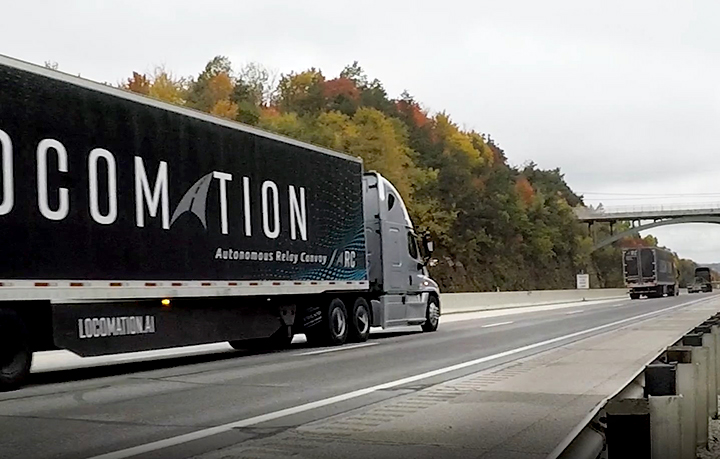

Motorists in Pennsylvania, Ohio and Michigan on Oct. 22 might have noticed a matching pair of tractor-trailers playing “follow the leader” along the interstates and turnpikes. The convoy was part of a Level 1 automated truck platooning demonstration that began in Pennsylvania, continued through Ohio and ended in Michigan, traveling more than 280 miles. The Smart Belt Coalition (SBC), a collaboration between transportation agencies and educational institutions in Pennsylvania, Ohio and Michigan, partnered with Locomation, a Pittsburgh-based technology firm, to complete the demonstration. SBC members include the American Center for Mobility, Carnegie Mellon University, Kettering University, the Michigan Department of Transportation (MDOT), the Ohio Department of Transportation’s (ODOT) DriveOhio initiative, Ohio State University, the Ohio Turnpike and Infrastructure Commission, the Pennsylvania Department of Transportation (PennDOT), Pennsylvania State University, the Pennsylvania Turnpike Commission, the University of Michigan and the Transportation Research Center Inc. While performing the demonstration, the SBC coordinated food donations between The Greater Pittsburgh Community Food Bank, the Toledo Northwestern Ohio Food Bank and the Forgotten Harvest Food Bank in Detroit. Truck platooning is the linking of two or more trucks in convoy using technology and automated driving-support systems. These vehicles automatically maintain a set, close distance between each other when they are connected. Truck platooning is considered SAE Level I automation. The SBC and Locomation demonstrated the agency coordination and administrative and procedural requirements necessary for a truck platooning system to operate continuously through multiple states. In March 2020, ODOT and DriveOhio issued a request for information (RFI), on behalf of all SBC members, for companies willing to demonstrate truck platooning and/or automated driving operations through the three partner states on roadways operated by the five SBC transportation and toll-road agencies. Through the RFI process, the coalition further engaged Locomation, which is developing a trucking technology platform to combine AI-driven autonomy with driver augmentation. The Oct. 22 deployment was the successful conclusion of that RFI process. “In Ohio, we are designing and deploying the transportation system of the 21st century,” said Ohio Gov. Mike DeWine. “Safety is our primary concern, and as smart mobility technologies mature, we believe these innovations will make our roads safer. Deployments, like this one, will help to inform future projects.” During the Oct. 22 demonstration, two platooning vehicles (tractor-trailers) were operated manually on surface streets. While on interstates and turnpikes, the lead truck was driven manually while the driver of the following tractor-trailer engaged the vehicle’s platooning technology. This technology augments the driver’s capabilities and enables the vehicle to follow the lead vehicle in the platoon. Both vehicles had an operator on board at all times. “Michigan has been at the forefront of developing mobility technologies of the future, and this demonstration follows others completed here to foster more research focused on safer ways to move freight,” Paul Ajegba, director of MDOT. “This furthers the culture of collaboration we’ve encouraged between private industry, government and academia to support research, testing and operations of automated vehicles.” In 2016 and 2017, MDOT partnered with the U.S. Army Combat Capabilities Development Command Ground Vehicle Systems Center to conduct platooning demonstrations and test vehicle-to-infrastructure messaging using military vehicles. “As a state that has always been at the forefront of innovation and industry, it should be no surprise that Pennsylvania is an epicenter for automated vehicle research and development,” said PennDOT Secretary Yassmin Gramian. “As stewards of transportation safety and mobility in Pennsylvania, PennDOT has a critical role in helping to ensure that this new technology is developed and tested safely.” Formed in 2016, the SBC is a strategic transportation collaborative that includes 12 organizations located in Michigan, Ohio and Pennsylvania. The purpose of the SBC is to foster collaboration among multiple agencies and research affiliates from the three states, involving research, testing, policy, standards development, deployments, outreach and funding pursuits in the area of connected and automated vehicle technology, as well as other innovations in the transportation industry. “Many amazing things are happening in the automated vehicle space, and truck platooning is an example of that,” said Mark Compton, CEO of the Pennsylvania Turnpike Commission. “However, we seek to be strategic about these developments and above all, safe. The Smart Belt Coalition is a coordinated effort which crosses state lines and makes it possible for us to be engaged in tech-enabled business and transportation trends. Working together, we will be able to more effectively advance these emerging technologies for all motorists.”