Small difference, big impact: Keeping track of tire pressure

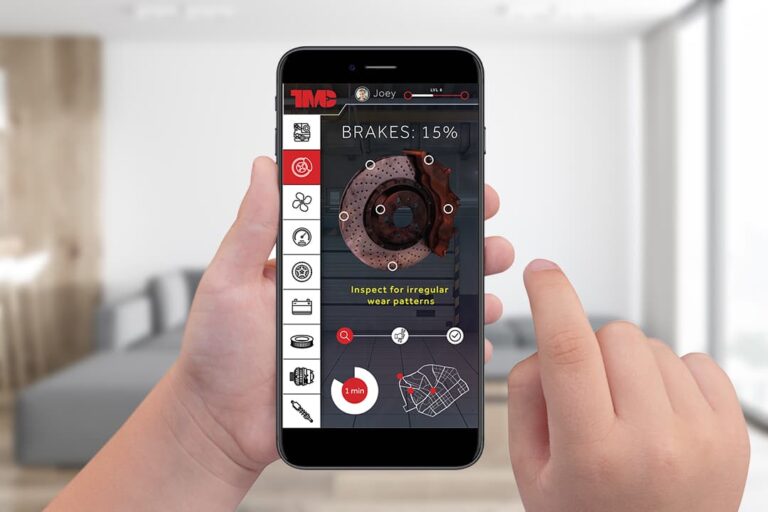

ELYRIA, Ohio — Often in trucking, it takes just a small change to make a big impact. This is especially true in tire pressure, where the difference of a few psi can directly affect mileage, maintenance, and safety. During National Tire Safety Week, May 20-27, Bendix Commercial Vehicle Systems stresses that with all that is riding on a truck’s tires — driver safety, operating performance, timely cargo delivery, and more — it’s vital to be sure of the right pressure in them. Sponsored annually by the U.S. Tire Manufacturers Association (USTMA), National Tire Safety Week is an initiative aimed at providing information on the essentials of proper tire care and maintenance. “Proper tire inflation will substantially impact your tire and ultimately your vehicle’s performance,” said Jon Intagliata, Bendix product manager for Tire Pressure Monitoring Systems (TPMS). “Fuel consumption can increase, stopping distances can increase, and tread life can decrease if the tires run on significantly different psi than what is recommended by the manufacturer — all of which can dramatically affect a fleet’s total cost of ownership (TCO) over the long haul, too.” According to the American Trucking Associations’ Technology & Maintenance Council, running on a tire that’s underinflated by as little as 10 percent can reduce fuel economy by 1.5 percent. And 20 percent underinflation can shorten tire life by 30 percent. The more miles driven and the more wheel-ends in a fleet, the bigger the impact those few psi have on the bottom line. Underinflated tires also experience increased stress and generate higher running temperatures, compounding the risk of tire blowouts – about 90 percent of which are the result of underinflation, according to industry studies. Real-Time Info on the Road “Gradual tire pressure loss can be difficult to detect, and you could be quite a way down the road before you have a chance to notice it at the next spot check,” Intagliata said. “That’s why the best tool for tracking the proper psi on each tire is a technology like the SmarTire Tire Pressure Monitoring System by Bendix CVS – or the SmarTire Trailer-Link TPMS by Bendix CVS for trailers: When drivers get real-time information and pressure alerts, they’re better equipped for safer trucking. Early notification makes all the difference in addressing problems before they become hazards.” It takes as little as a 5 psi difference between dual-mounted tires to create problems, including irregular or accelerated tire wear. Bendix uses wheel-mounted sensors inside the tires on its SmarTire systems, allowing the TPMS to continuously monitor temperature inside the tire as well as pressure. This means the system can provide a deviation value showing the amount of overinflation or underinflation from the tire’s cold inflation pressure (CIP), automatically taking into account any increase in pressure due to temperature to provide early alerts of tire pressure issues. Reading temperature also helps the system alert the driver to potential wheel-end issues, such as dragging brakes, and may help the driver mitigate potential tire fires. Fleets running TPMS-equipped vehicles can also use the system data to shape their tire strategy and maintenance plans by using a back-office system like SafetyDirect by Bendix CVS – a web portal that allows analysis of real-time information from TPMS and other connected safety technologies. Fleets can maximize uptime by planning vehicle service in advance and more effectively address issues such as frequent tire replacements and tire failures on the road. High Tech, High Stakes As vehicle safety technologies have advanced and higher regulatory standards have evolved – antilock brakes, Reduced Stopping Distance requirements, and the full-stability mandate, for instance – the importance of tires in good condition running at proper inflation has increased. Moving forward, collision mitigation and other advanced driver assistance systems (ADAS) remain dependent upon precise and controlled interaction among the men and women behind the wheel, their vehicles, and the road itself – where tires are the sole point of contact. “Today’s integrated vehicles mean you need to equip the best set of tools on your tractor and trailer to maximize performance,” Intagliata said. “TPMS can play a critical role to guarantee your advanced safety systems – including air disc brakes and advanced driver assistance technologies – are functioning at the optimal levels.” According to Intagliata, “Like any safety system, a TPMS is meant to complement safe driving practices and is not intended to enable or encourage aggressive driving. No technology can replace skilled, alert drivers exercising safe habits, or the support of proactive, comprehensive driver training – the safe operation of any vehicle remains with the driver at all times.” Bendix® SmarTire and SafetyDirect are part of Bendix’s full suite of technologies delivering safety, vehicle performance, and efficiency, backed by unparalleled post-sales support: areas critical to the success of fleets and owner-operators. By strengthening return on investment in advanced equipment that puts drivers behind the wheels of safer trucks, Bendix lowers total cost of ownership and helps enhance highway safety across North America. To learn more about Bendix TPMS, call 1-800-AIR-BRAKE or visit bendix.com. For deeper insight on Bendix technology and the commercial vehicle landscape through podcasts, blogs, videos, and more, visit the Knowledge Dock at knowledge-dock.com.