ELYRIA, Ohio — On a single day this past May, nearly 1,700 commercial vehicles were taken off the roads of North America because of brake system safety violations: Consider for a moment if just half of those – or a quarter, or even just one – had been unable to stop in a critical situation because of a brake system that wasn’t in good operating condition. That kind of moment is exactly why Bendix (Bendix Commercial Vehicle Systems LLC and Bendix Spicer Foundation Brake LLC) works to help fleets and owner-operators prepare for events like Brake Safety Week 2019, which will take place September 15-21.

Part of the Commercial Vehicle Safety Alliance’s (CVSA) Operation Airbrake, Brake Safety Week is an outreach and enforcement campaign that aims to reduce the number of crashes caused or made more severe by faulty brake systems on commercial motor vehicles. Inspections on large trucks and buses will be conducted by local, state, provincial, territorial and federal motor carrier safety officials in the United States and Canada. Bendix, a North American leader in the development and manufacture of active safety, air management and braking system technologies for commercial vehicles, supports the CVSA’s goals of improving vehicle safety throughout the United States, Canada and Mexico.

“What’s at stake is more than just avoiding noncompliance penalties and out-of-service time – although those are certainly of importance,” said Barbara Gould, Bendix director of corporate communications. “The most important reason we stress preparation for inspection periods like Brake Safety Week is because drivers need to be able to depend on their brakes every moment of every mile. And even as advanced safety technologies like full stability and collision mitigation enhance a vehicle, those systems still require brakes in good working condition to support drivers and perform at their best.”

On May 15, during an unannounced inspection blitz in the United States and Canada, CVSA law enforcement members conducted 10,358 commercial motor vehicle inspections focused on identifying brake system violations. Of those vehicles inspected, 1,667 (16.1 percent) were placed out of service due to critical brake-related violations. This year’s Brake Safety Week includes a special focus on brake hoses/tubing. May’s inspections found 1,125 violations that included chafed hoses, and 124 that included kinked hoses. According to the Federal Motor Carrier Safety Administration’s data for the first half of 2019, brake hose or tubing chafing and/or kinking accounted for nearly 38,000 inspection violations.

“Hoses and tubing affect the performance of an entire braking system, so it’s important that they’re in good shape and free of kinks,” said Brian Screeton, Bendix supervisor for technical service training. “Checking their condition, positioning and connections should be a regular part of any visual inspection, both during pre-trip walk-arounds and in the shop. Additionally, we recommend that every driver makes performing regular 90- to 100-psi brake applications and listening for leaks part of their preparation before getting on the road.”

“Hoses and tubing affect the performance of an entire braking system, so it’s important that they’re in good shape and free of kinks,” said Brian Screeton, Bendix supervisor for technical service training. “Checking their condition, positioning and connections should be a regular part of any visual inspection, both during pre-trip walk-arounds and in the shop. Additionally, we recommend that every driver makes performing regular 90- to 100-psi brake applications and listening for leaks part of their preparation before getting on the road.”

Other pre-trip and preventive maintenance items directly related to Brake Safety Week inspections include:

- Daily visual checks for damaged or loose-hanging air chambers, pushrods or slack adjusters. (Note that slack adjusters on each axle should be extended out to the same angle: If not, it could indicate an out-of-adjustment brake or a broken spring brake power spring.)

- Weekly checks of air disc brake rotors for cracks, and lining wear on drum brakes.

- Monthly checks for moisture in the air system. (Contamination can lead to deterioration of air seals, brake-modulating valves, and brake chamber diaphragms, leading to system leaks.)

- Regular greasing of S-cam brake tubes and automatic slack adjusters to prevent rust and corrosion.

Proper brake adjustment is also a part of CVSA roadside inspections and should be addressed in the shop in advance of the event. While air disc brakes include an internal adjustment mechanism, drum braked wheel-ends will need to have their brake stroke measured.

“Measuring the chamber stroke involves checking the distance from the air chamber to the clevis pin with the brakes released, and again after a fully charged brake application,” said Keith McComsey, Bendix Spicer Foundation Brake director of marketing and customer solutions – Wheel-End. “Drivers can incur fines if the difference between those two measurements – the chamber stroke – is outside allowable limits on 25 percent of a truck’s wheel-ends.”

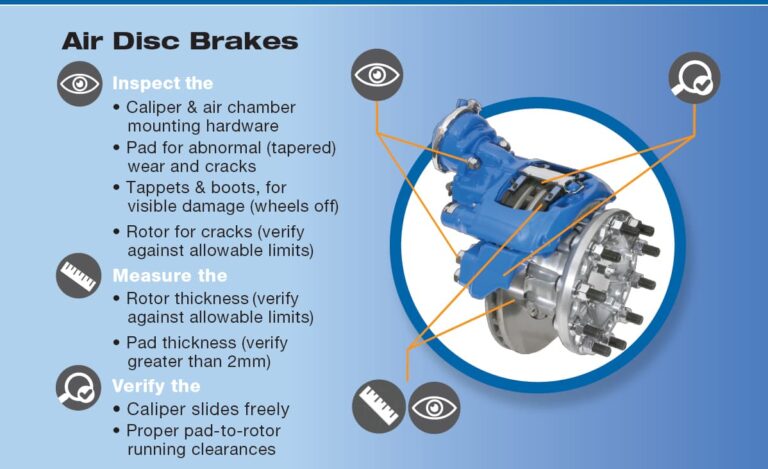

The Bendix technical support team has developed an infographic (shown above) to note differing maintenance needs of air disc and drum brakes.

Brake Safety Week inspectors will primarily conduct the North American Standard Level I inspection, covering a range of driver qualifications, documentation, and vehicle equipment conditions. Other brake system points of interest include mismatched air chamber sizes across axles, and warning device functionality, including antilock braking system indicator lights. Fourteen Brake Safety Week inspection jurisdictions will also be using performance-based brake testing (PBBT) to measure vehicle braking efficiency.

In addition to short-term preparation for inspections, there are long-term paths available for ensuring healthy braking systems and properly functioning technologies.

The right wheel-end friction selection is one example: Not all replacement linings marketed as acceptable for federal stopping distance requirements will actually perform to the standard, and the wrong choice may lead to cracks, missing pieces or degradation – any of which can earn violations during a roadside inspection.

In addition, when replacing drum brake shoes, choose remanufactured shoes that have been coined back to their original OEM-engineered shape over those that have simply been relined. Even normal brake usage affects the shape of a shoe, and relining it – rather than coining – can lead to reduced stopping power and premature wear.

Because oil aerosols entering an air brake system can be particularly corrosive, Bendix advises using an oil-coalescing air dryer cartridge like the Bendix PuraGuard. Oil-coalescing cartridges can be used to replace standard cartridges, but never vice-versa.

“Today’s commercial vehicles and their safety systems are more proven and effective than ever – but it takes professional technicians and drivers dedicated to safer roads to help keep them running smoothly,” Gould said. “And there’s a lot to keep track of – that’s why our team works to support those efforts and shares its expertise through in-person programs and online resources: Because we’re shaping tomorrow’s transportation together, and everyone benefits when we’re all focused on safety.”

Through industry technical leadership, unparalleled post-sales support, and an ever-growing portfolio of technology developments, Bendix delivers on safety, vehicle performance, and efficiency, supporting areas critical to fleets’ success. In striving to lower the total cost of vehicle ownership, Bendix helps strengthen return on investment in equipment and technology that enhance safety for all drivers and passengers who share North America’s roads.

For more information about Bendix air brake systems and technologies, call 800-AIR-BRAKE (800-247-2725) or visit safertrucks.com/solutions.

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.

Bendix urges drivers to prepare for Brake Safety Week, offers checklist

Comment