The calendar is set.

The eyes of every trucking company, independent driver and the rest of those that make up the trucking industry are looking toward 2027.

That is when the Environmental Protection Agency (EPA) has mandated zero emission standards.

Those standards’ specifics are as difficult to decipher and apply as a calculus word problem, but Cummins appears to have a handle on how 2027 might look with the new X15 engine.

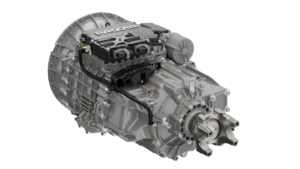

In a walk-around tour of the new Cummins X15 engine for a gathering of media on Aug. 13, Cummins executives unveiled their new engine platforms.

The X15 series has three models — including one for advanced diesel, natural gas and hydrogen.

The goal is obviously peak performance over the long haul, which includes increased fuel economy, lower emissions, and more time on the road.

Much of the design of the X15 has been to make the engine lighter. Cummins engineers have achieved this by taking much of the components of the engine and make them noticeably lighter.

One that was noticeable was the change in the structure of the engine’s pistons.

While the exact weight of the piston wasn’t known, if the two were compared by lifting both the old and the new, it was indeed lighter.

“I think a lot of what we are trying to do … is improve the overall CO2 performance of the engine, make the engine lighter,” said Tom Marsh, who serves as the VPI leader for the X15. “Improve in all of those areas, but at the same time, maintain the robustness of the product, but also adopt the global platforms.”

Along with lighter, more compact pistons, is the evolution of a new fuel pump.

Marsh said the new fuel pump was an attempt to course correct from issues that have been prevalent for many years.

“What we have done is learn from all of those things,” Marsh said.

The new pump has been designed to “design out” some of previous failures.

“The whole design is more compact,” Marsh said.

The fuel filter and oil filter have also been streamlined. The new oil filter has a plastic design, and is made to make changes easier by draining oil and simply replacing media which hasn’t changed from the older, heavier metal housing. At launch, aftermarket will be able to capture the filter as well.

A new closed crank case was a solution, not only to help lighten the engine, but to also help comply with new emission standards. The closed crank case eliminates tail-pipe emissions according to Marsh. That means a more efficient breather. That breather on the side of the engine is maintenance free.

Another regulation for 2027 that the X15 complies with is cybersecurity. The intent is that no one could connect over the air with any systems relating to the engine, changing the way the engine operates. That technology is built in to the product.

The engine was tested through several years including 18,700 hours of in-house and overload testing and nearly 6 million miles of on-road testing.

What the future holds for the industry as far as regulatory requirements for emissions, whether the next White House administration will make emission standards more challenging going forward, or if states are left to fend for themselves, Cummins has taken a necessary step in order to be ready, no matter what happens when the calendar flips to 2027.

Bruce Guthrie is an award-winning journalist who has lived in three states including Arkansas, Missouri and Georgia. During his nearly 20-year career, Bruce has served as managing editor and sports editor for numerous publications. He and his wife, Dana, who is also a journalist, are based in Carrollton, Georgia.