STUTTGART, Germany — State-of-the-art production facilities, which will serve as a technological template for series production of fuel cells, are in the developmental stages at Daimler Truck AG. During the past decade, experts at Daimler have built up extensive knowledge of the field and worked to develop production methods and processes, according to a June 30 statement from Daimler.

“We are pursuing the vision of the CO2-neutral transportation of the future. The hydrogen-based fuel cell is a key technology of strategic importance in this context,” said Martin Daum, chairman of the board of management for Daimler Truck AG and member of the board of management for Daimler AG. We are now consistently following the path towards the series production of fuel cells and are thus doing absolutely pioneering work — and this goes beyond the automotive industry. We will invest a very substantial sum in the coming years to achieve this.”

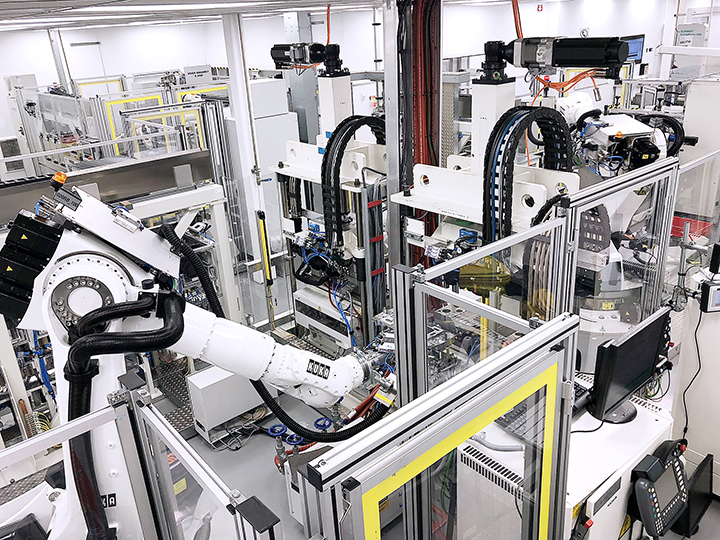

In cooperation with colleagues in Vancouver, Canada, and with the ongoing fuel cell development activities, Daimler’s Stuttgart-based experts are applying this knowledge and experience to the direct preliminary stage of future series production. Investments are being made in new state-of-the-art facilities covering every single process stage of fuel cell production, from membrane coating and stack manufacturing to the production of fuel cell units.

“As with the development of fuel cell technology, we benefit also in the field of production from our experts’ many years of experience, said Andreas Gorbach, head of Daimler Truck Fuel Cell. “This gives us an enormous competitive advantage: We are already in a position to work specifically on one of our most important milestones, namely the technological template for the series production of fuel cell systems on a large industrial scale.”

New production technology for highly complex, highly sensitive products

Conventional industrial production processes cannot be directly transferred to the highly complex, highly sensitive fuel cell stacks. For example, the processing of numerous delicate components takes place in the micrometer range (1 micrometer = 1 millionth of a meter). Even the smallest contamination could impair the functionality of the fuel cells, which is why a clean room with filtered air is being set up for some of the work in the planned pre-series production. Optimizing the ambient air in production is also especially important, since even slight fluctuations in temperature and humidity can lead to significant material changes. This would make further work in subsequent processes considerably more difficult. However, the greatest challenge for the Daimler experts is to achieve short production cycles, which is essential for cost-effective production. For this reason, the experts in the production of fuel cell stacks sometimes rely for example on technologies from the packaging industry, which are generally not used in conventional engine production.

Planned fuel cell joint venture between Daimler Truck AG and the Volvo Group

In April this year, Daimler Truck AG concluded a preliminary, nonbinding agreement with the Volvo Group to establish a new joint venture for the development and marketing of fuel cell systems to be used in heavy-duty commercial vehicles and other applications. The joint venture will draw upon expertise from both Daimler Truck AG and the Volvo Group.

The production of fuel cell systems is also to be included in the joint venture. Daimler Truck AG and the Volvo Group plan to offer heavy-duty fuel cell commercial vehicles for demanding and heavy-duty long-distance haulage from series production in the second half of this decade.

To facilitate the joint venture with the Volvo Group, Daimler Truck AG is bringing together all group-wide fuel cell activities in the recently established subsidiary Daimler Truck Fuel Cell GmbH & Co. KG; this also includes the activities of Mercedes-Benz Fuel Cell GmbH. Daimler Truck Fuel Cell GmbH & Co. KG will transition into the planned joint venture at a later date. Over the past decades, Daimler has acquired considerable expertise in the field of fuel cells at its site in Nabern, Germany (currently the headquarters of Mercedes-Benz Fuel Cell GmbH), and at other production and development facilities in Germany and Canada.

Planned cooperation with Rolls-Royce plc for stationary fuel cell systems

Specific opportunities for the commercialization of fuel cell technology through the planned joint venture between Daimler Truck AG and the Volvo Group are demonstrated by the cooperation planned between Daimler Truck AG and the British technology group Rolls-Royce plc in the field of stationary fuel cell systems. Rolls-Royce’s Power Systems division plans to use the fuel cell systems from the planned joint venture between Daimler Truck AG and the Volvo Group, as well as Daimler’s many years of expertise in this field, for the emergency power generators of the MTU product and solution brand it develops and sells for data centers. A comprehensive cooperation agreement will be drawn up and signed by the end of the year, according to Daimler.

The Trucker News Staff produces engaging content for not only TheTrucker.com, but also The Trucker Newspaper, which has been serving the trucking industry for more than 30 years. With a focus on drivers, the Trucker News Staff aims to provide relevant, objective content pertaining to the trucking segment of the transportation industry. The Trucker News Staff is based in Little Rock, Arkansas.

Daimler Truck AG works toward series production of fuel cells for commercial trucks

Comment